Press Automation

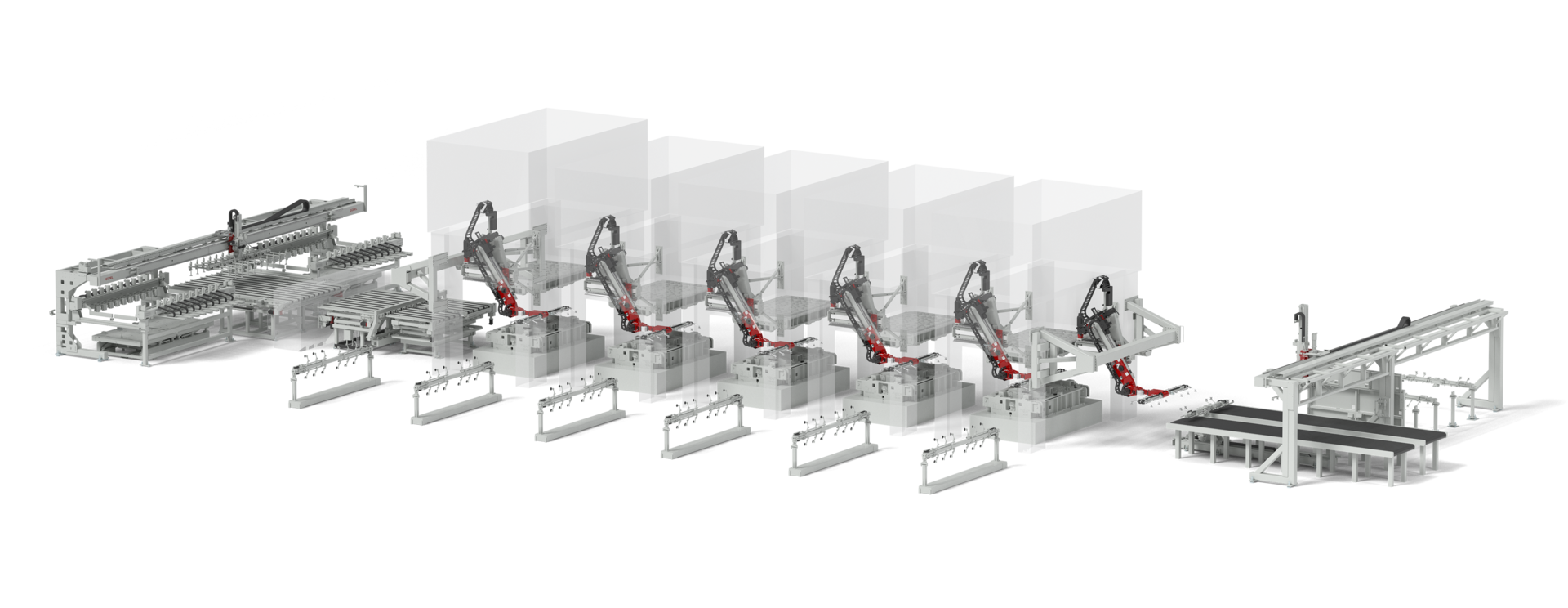

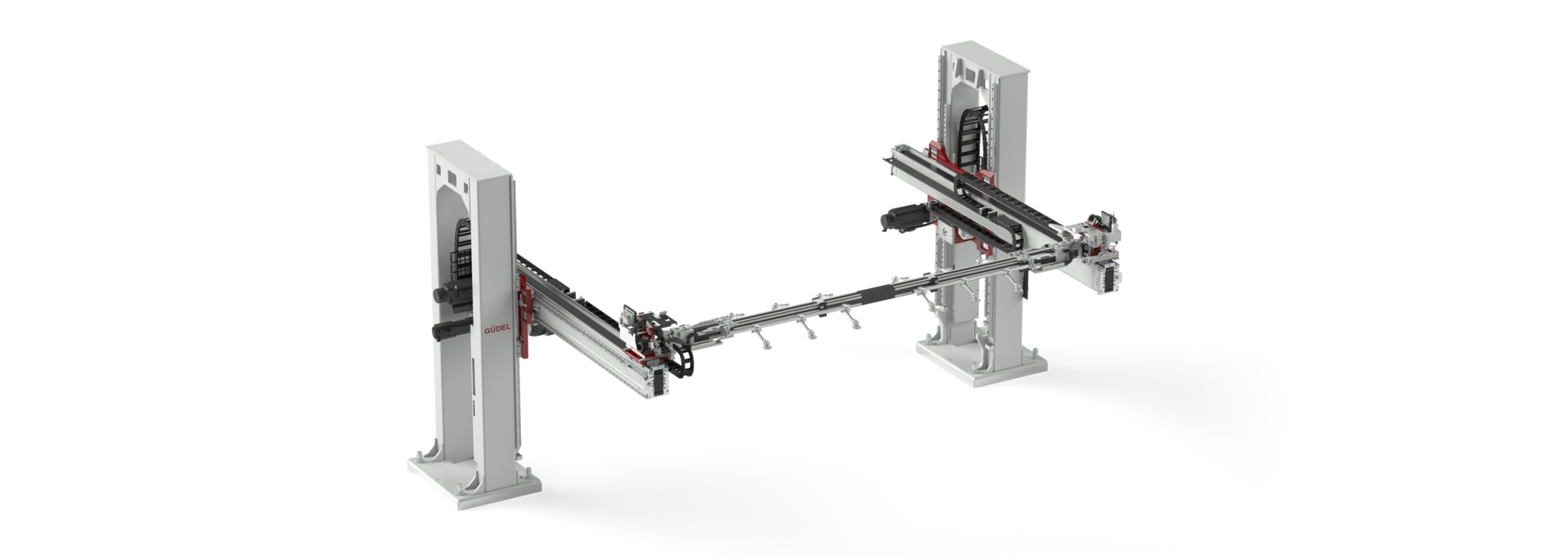

Güdel offers matching solutions for all subprocesses in the range of press automation, both in regard to new installations and press line re-vitalisation (retrofits) from destacking the blanks (Front of Line, FOL) to press to press transfer (Press Line Transfer, PLT) and finished part handling (End of Line, EOL). Our concepts and system solutions are constantly developed and continuously adapted to the increasing customer requirements. The focus is, of course, on increase of efficiency and high availability by cost-efficient additional digital tools and services.

Globally, up until today, over 200 press lines have been equipped with automation solutions from Güdel at more than 30 customers. This puts Güdel in the leading position as an automation supplier for L and XL sized press lines and makes Güdel a reliable worldwide operating automation partner.

We are looking forward to be your innovative and reliable automation partner.

Solutions

| description | industry | process | modal | |||

|---|---|---|---|---|---|---|

Blank Destacking System – Automatic fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Blank Destacking System – Automatic fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Details |

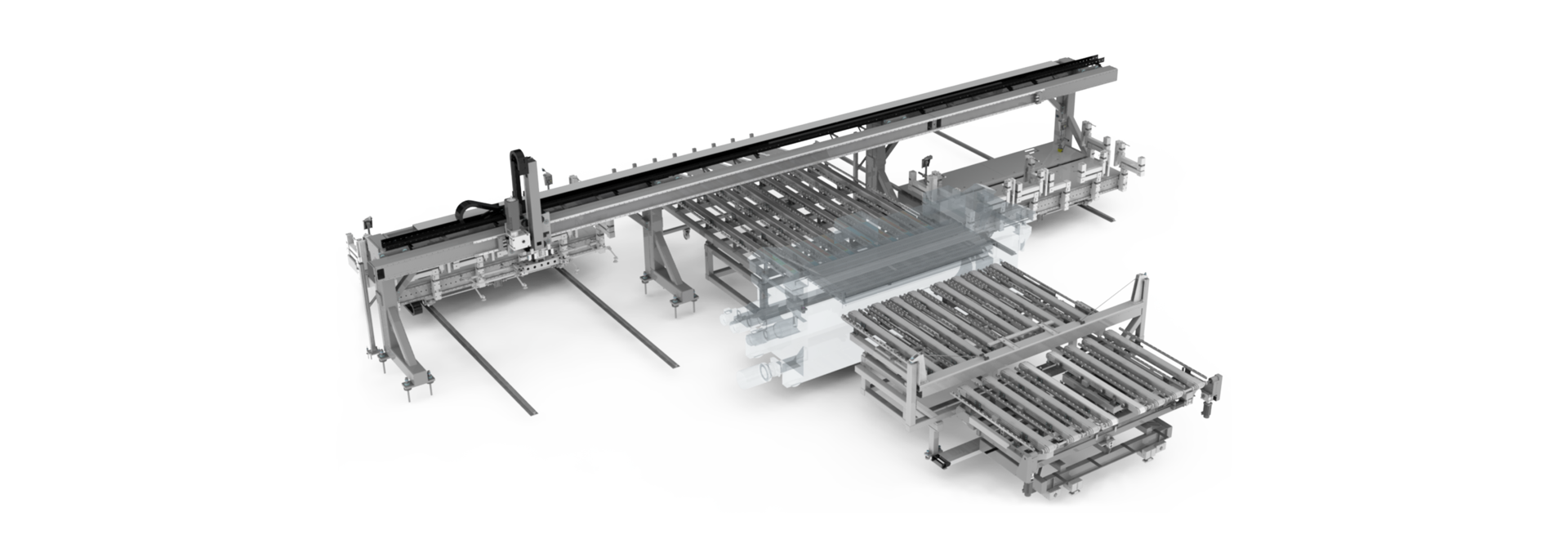

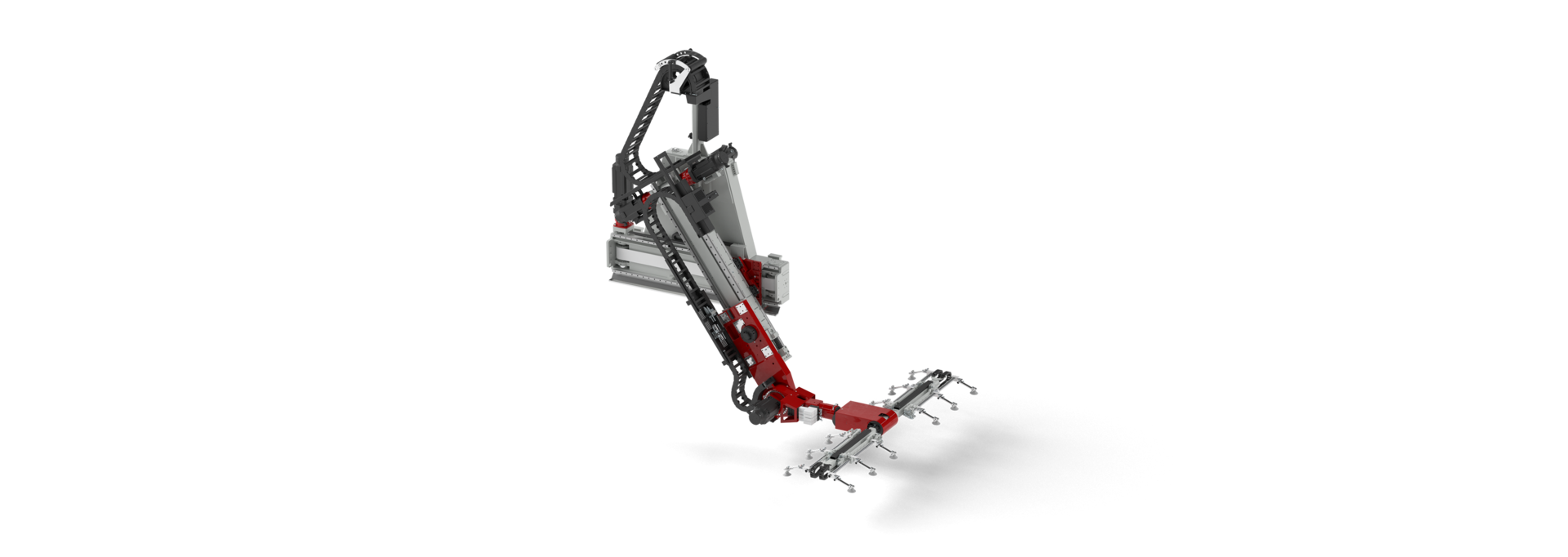

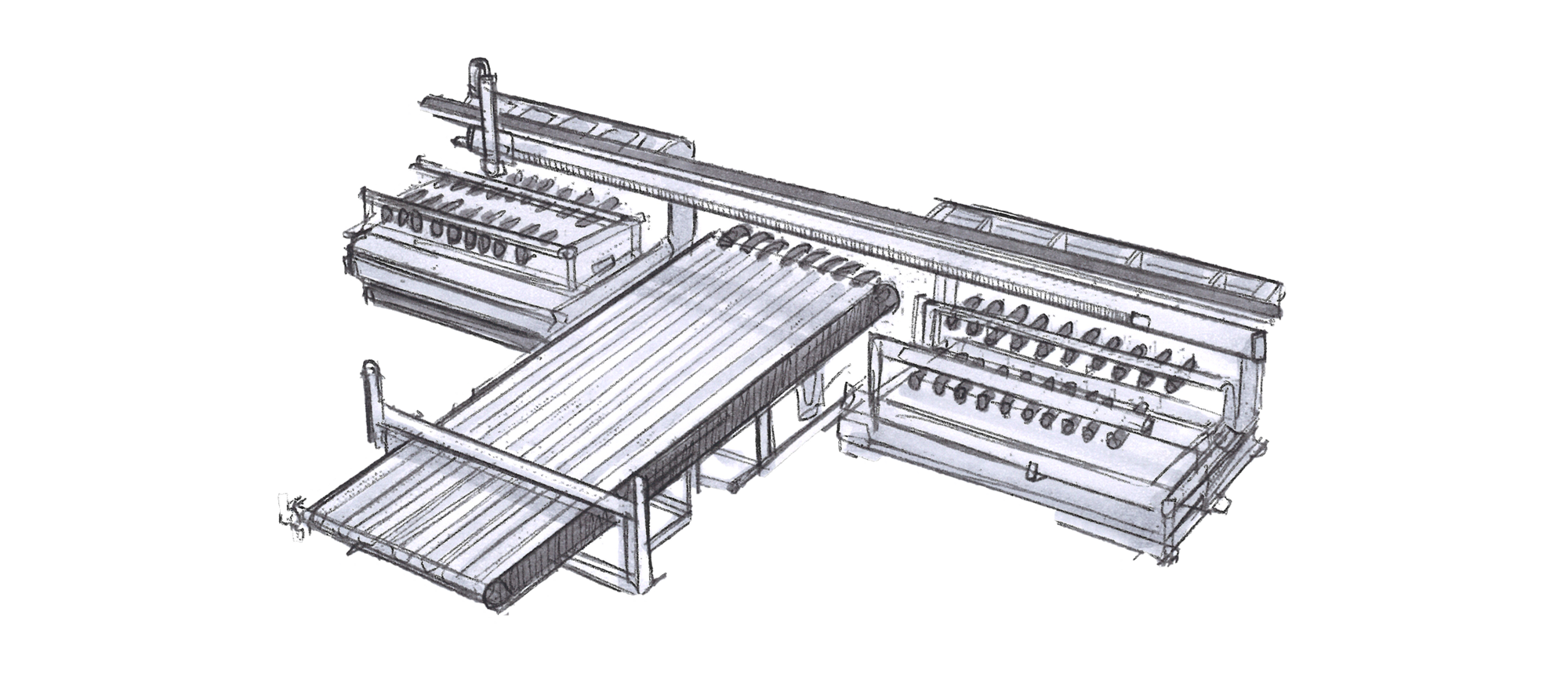

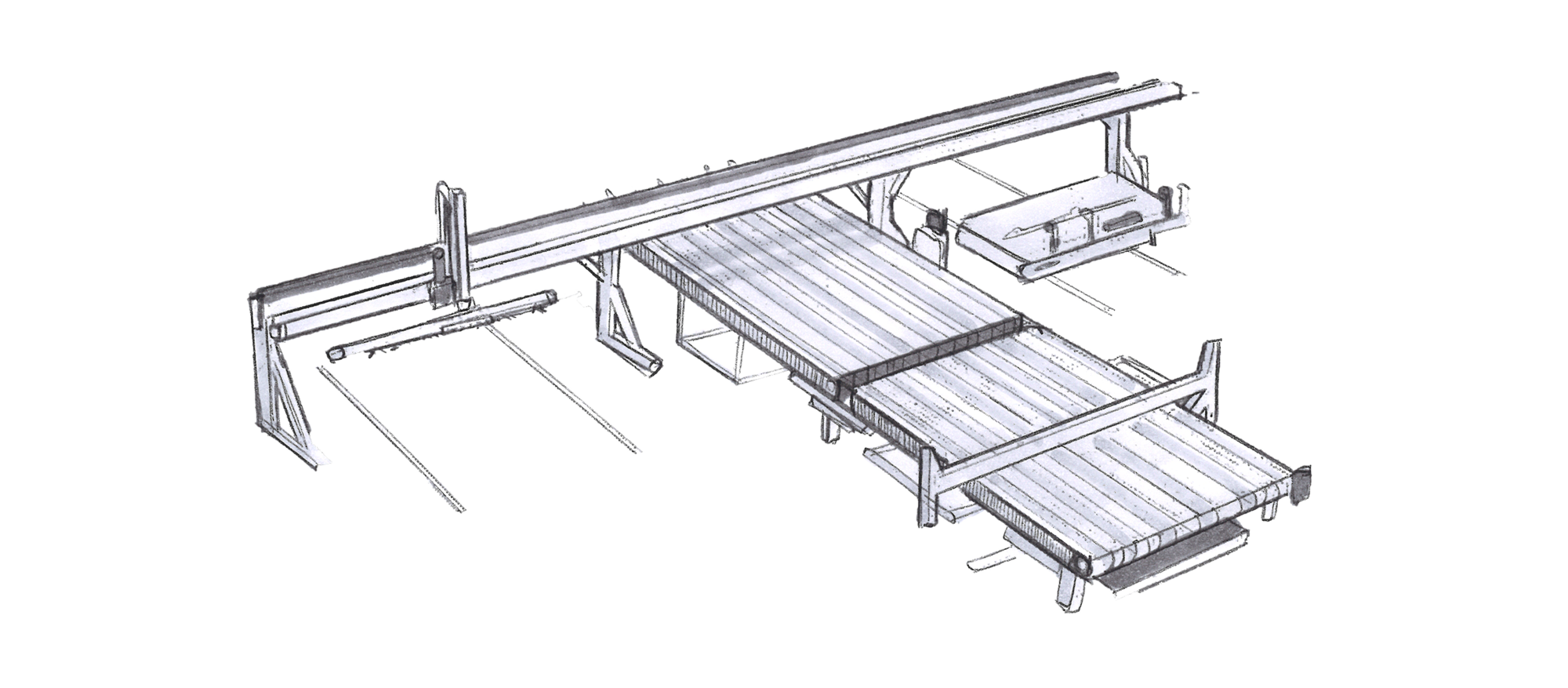

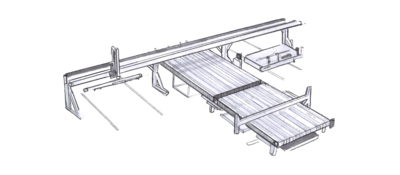

The Güdel blank destacking system is dedicated for feeding blanks to high speed tandem press lines. The fully automatic fanner magnets are positioned on a separate frame to ensure that the blank carriages can be easily loaded. The use of two scissor-lift tables for each blank carriage allows single and double blanks to be simultaneously processed even with different blank thicknesses. Aluminum blanks can be separated using blowing nozzles and processed in conjunction with vacuum conveyors without productivity loss. The combination of an optical parts recognition system and a centering station equipped with servo axes ensures that the entire spectrum of parts can be processed without the need for manual limit stops. Interested?

|

,8088, | ,7766, | modal-solution-7732 |

Blank Destacking System – Manual fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Blank Destacking System – Manual fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Details |

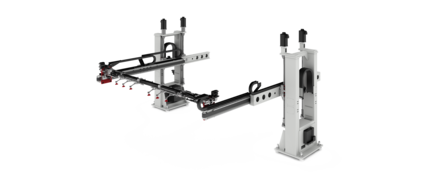

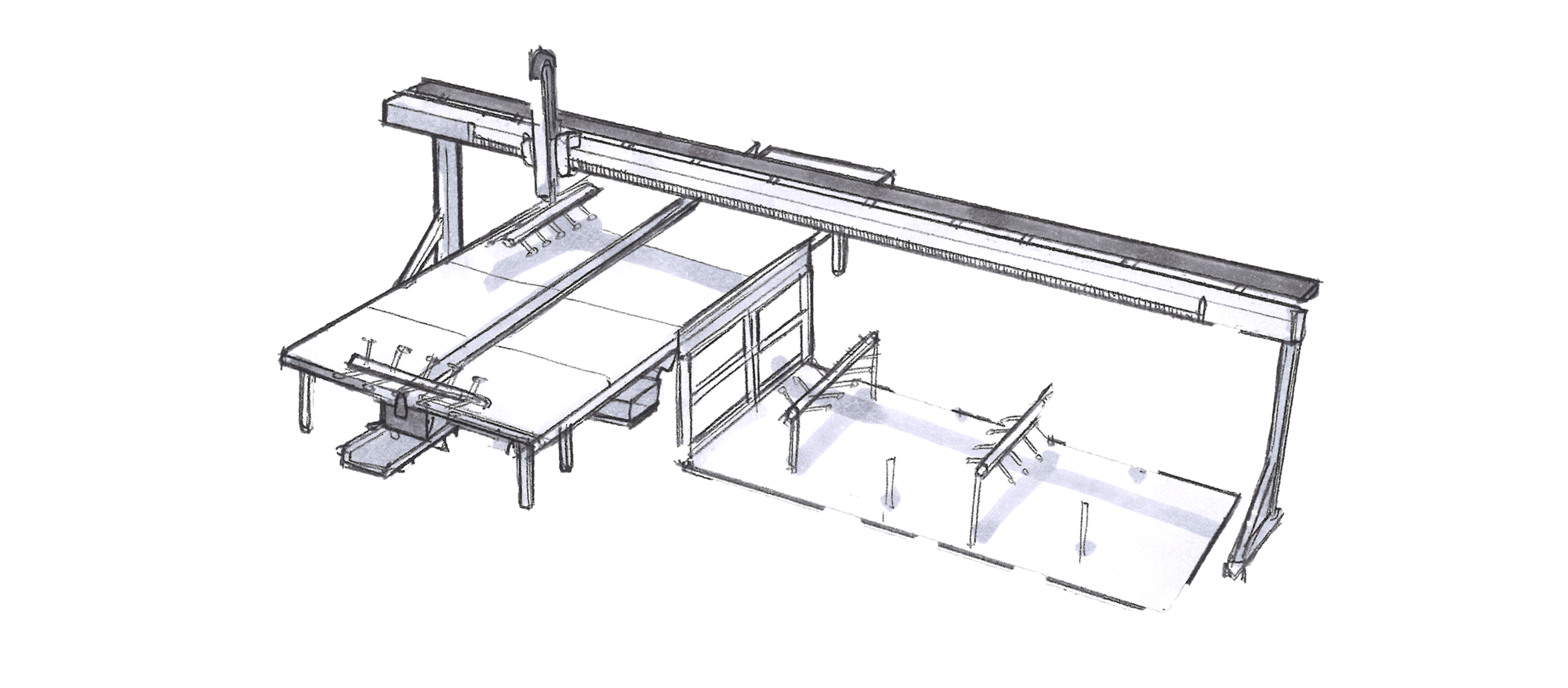

The Güdel blank destacking system is dedicated for feeding blanks to high speed tandem press lines. The fanner magnets are moved towards the blank stack manually by means of the easy-to-use rotary arms. Blowing nozzles located next to the fanner magnets enable aluminum blanks to be processed. The system is also suitable for processing single and double blanks.

The combination of an optical parts recognition system and a centering station equipped with servo axes ensures that the entire spectrum of parts can be processed without the need for manual limit stops.

Interested?

|

,8088, | ,7766, | modal-solution-7537 |

End of Line – Semi-automaticSwift, ergonomic stacking of finished parts |

End of Line – Semi-automaticSwift, ergonomic stacking of finished parts |

Details |

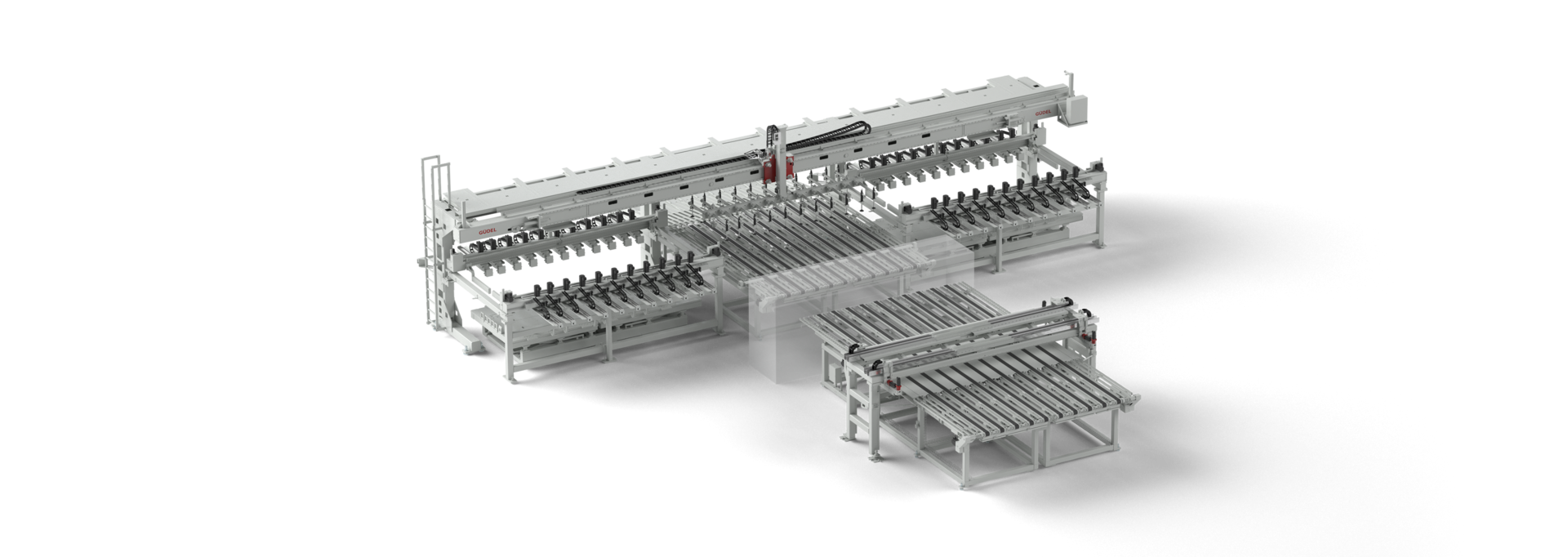

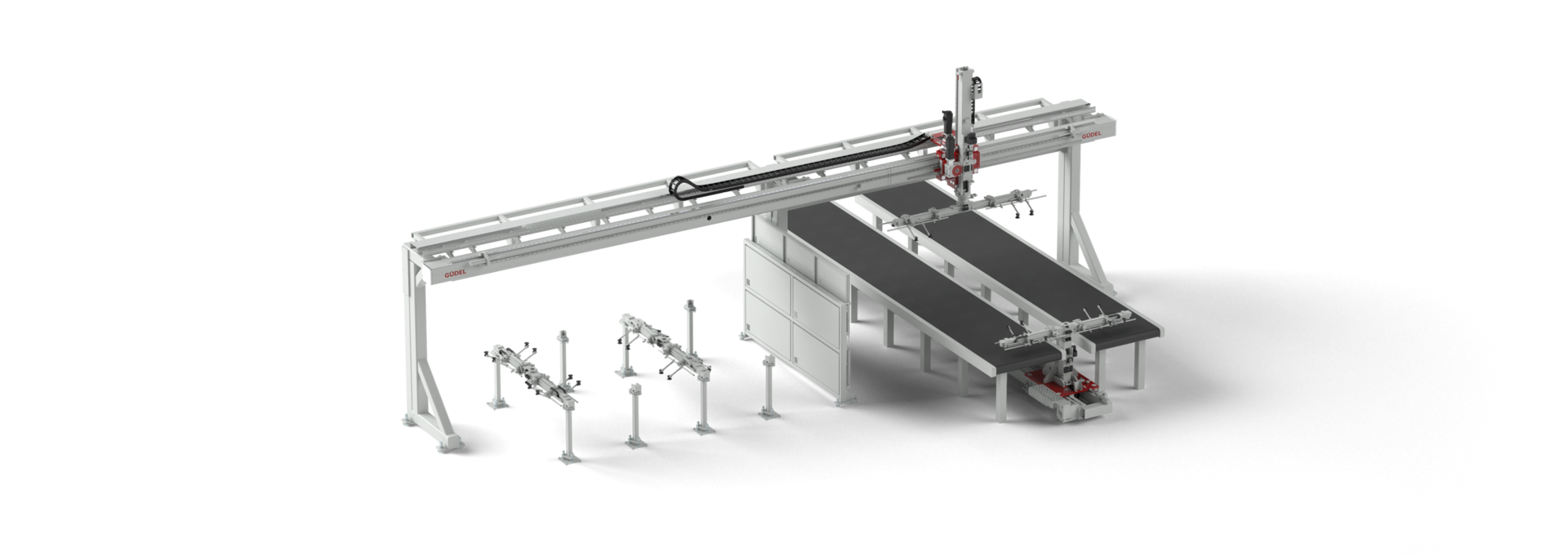

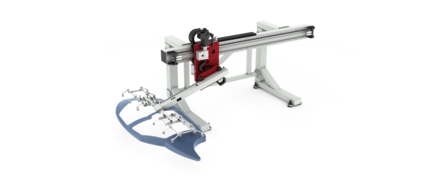

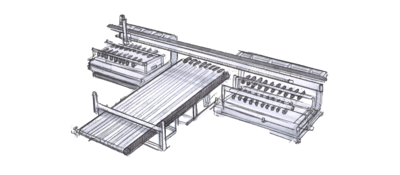

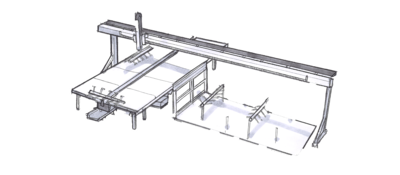

A particularly striking feature of our semi-automatic finished parts stacking solution is its excellent cost-benefit ratio. The EOL solution allows finished parts to be arranged ergonomically on the removal belt, so that the parts can be manually removed more swiftly and carefully. Equipped with a gantry and a parts shuttle with integrated separating units, the system is flexible enough to place the parts almost anywhere on the outlet conveyor. Interested?

|

,8088, | ,7766, | modal-solution-7911 |

Press line automationUp to 21 parts handled per minute |

Press line automationUp to 21 parts handled per minute |

Details |

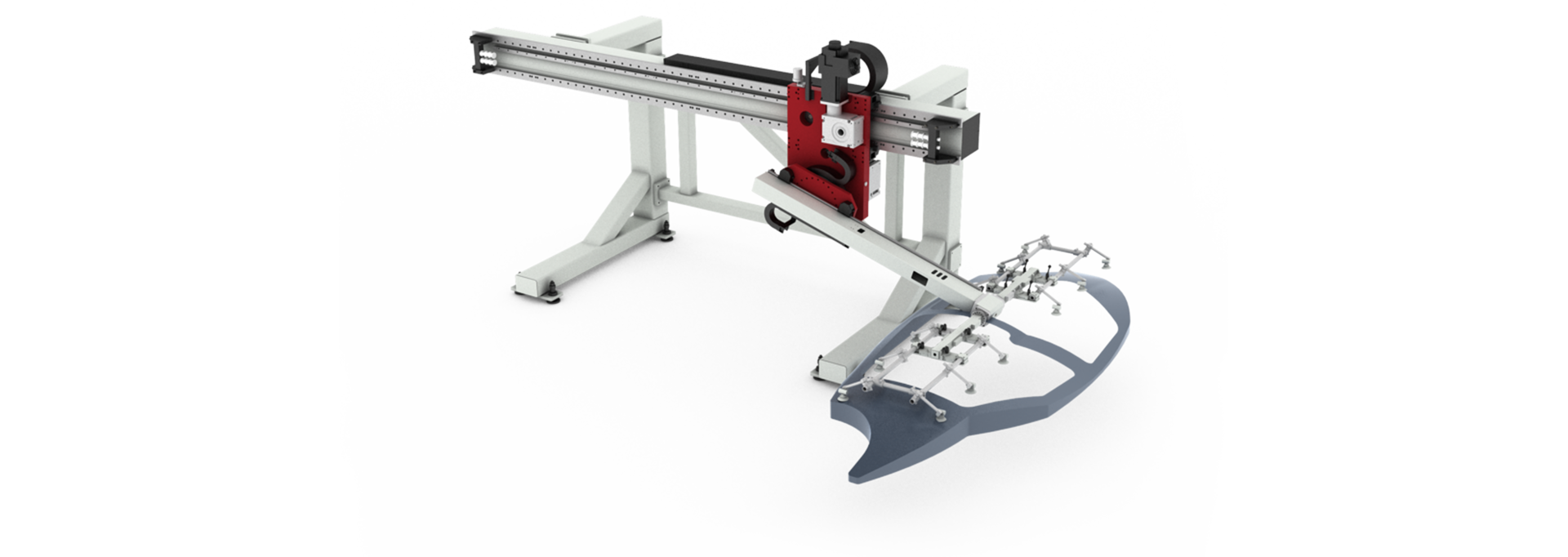

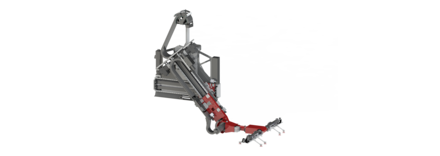

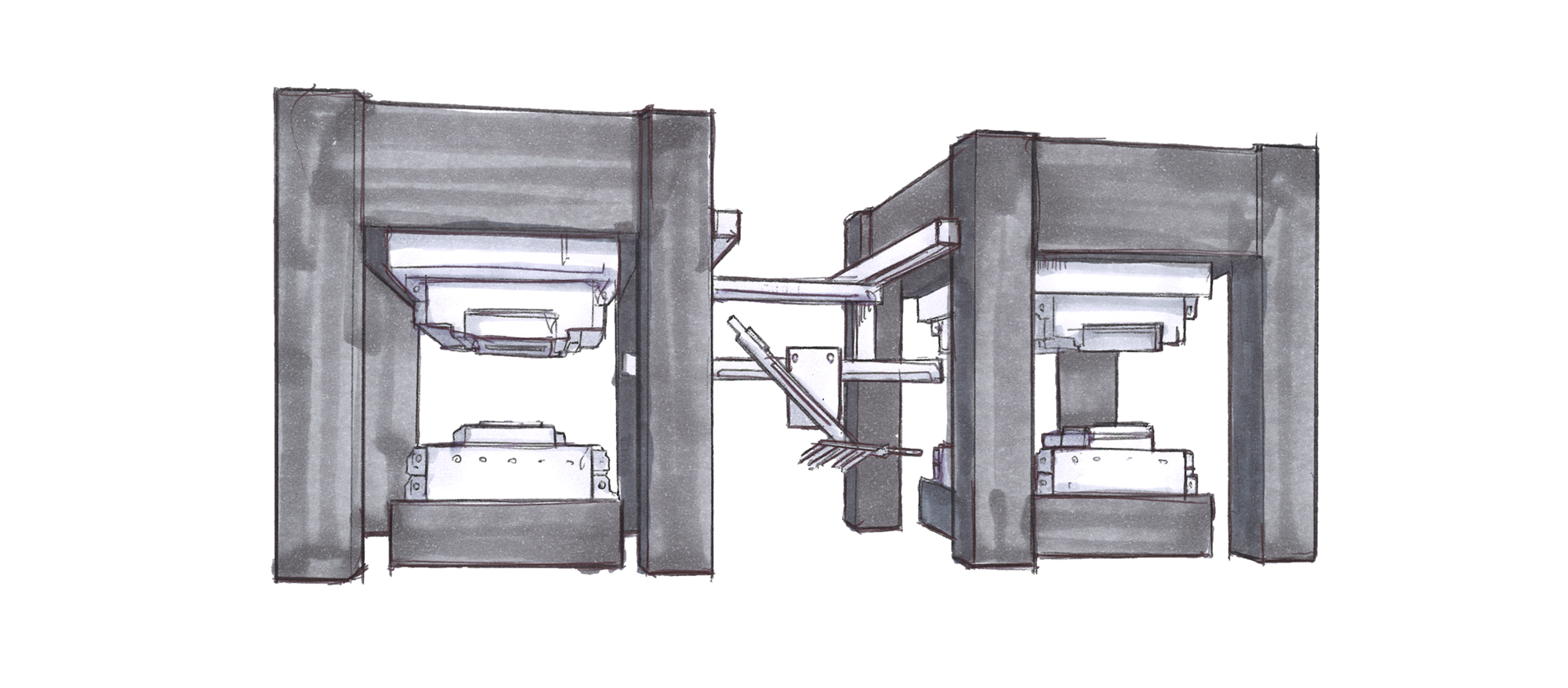

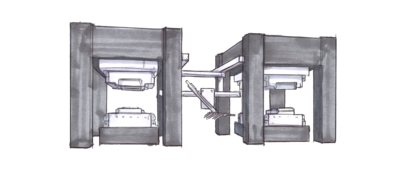

For a smooth flow, even between presses: our sophisticated parts transfer system can handle up to 21 parts per minute with speed and reliability guaranteed. Our transfer robots are characterized in particular by rigid mechanics and highly dynamic, low-vibration movements.

Interested?

|

,8088, | ,7766, | modal-solution-7987 |