About Güdel

Precision, innovation and passion in every motion

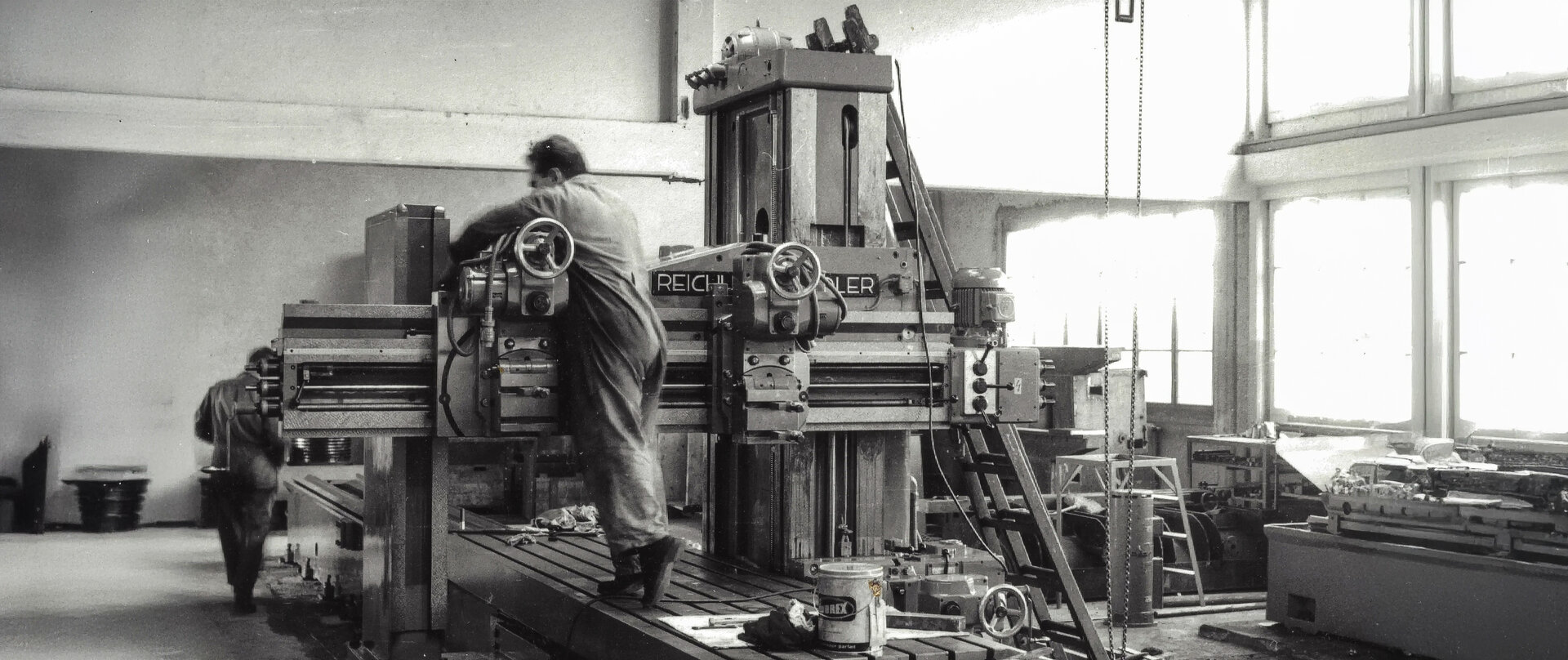

Güdel is an international swiss industry group founded in 1954. As one of the world's leading suppliers of industrial automation solutions, Güdel offers its customers everything from a single source: from high-precision machine components to customised automation solutions for use in the automotive, railway, logistics and machine tool industries, among others.

Güdel employs around 1000 people in more than 20 locations worldwide. The group has been owned by the founding family since its foundation.